- Docs

- Order Builder Overview

- Plan Reports for Order Builder

-

Installation

-

Updating

-

Settings

-

Logs

-

API

-

Reports

-

Snapshots

-

Workflows

-

Dashboard

-

Explorer

-

Users

-

Resources

-

Custom Fields

-

Cycle Counts

-

Data Pull

-

Data Push

-

Displays

-

Lights (Philips Hue)

-

Order Builder

-

Order Processor

-

Variance

Plan Reports for Order Builder

A well-designed ItemPath report is crucial for effective order automation with Order Builder. The report acts as the foundation for order generation, with each row representing a trigger for creating an order (or order line).

Note: Data from your reports can populate fields on orders created by Order Builder. For example, you can use the "Location Name" and "Material ID" columns to automatically fill the corresponding fields in your replenishment orders. Be sure to include all the necessary data in your report to streamline order creation and reduce manual data entry.

Define a scenario

Start by defining the specific scenario or "story" you want to automate. Identify what conditions need to trigger the order creation process, and whether you would like a user to review the orders before they are created in Power Pick. In the overview, we discussed the replenishment example. In this case, you would need to have a report show all materials at a location below a certain stock level. If a row is in the report, then that location should be used to create a replenishment order.

Once you have your scenario, you can design a report that captures the necessary data to trigger the desired orders. Here's an example of how to build a report to identify locations with quantities below a certain threshold for replenishment:

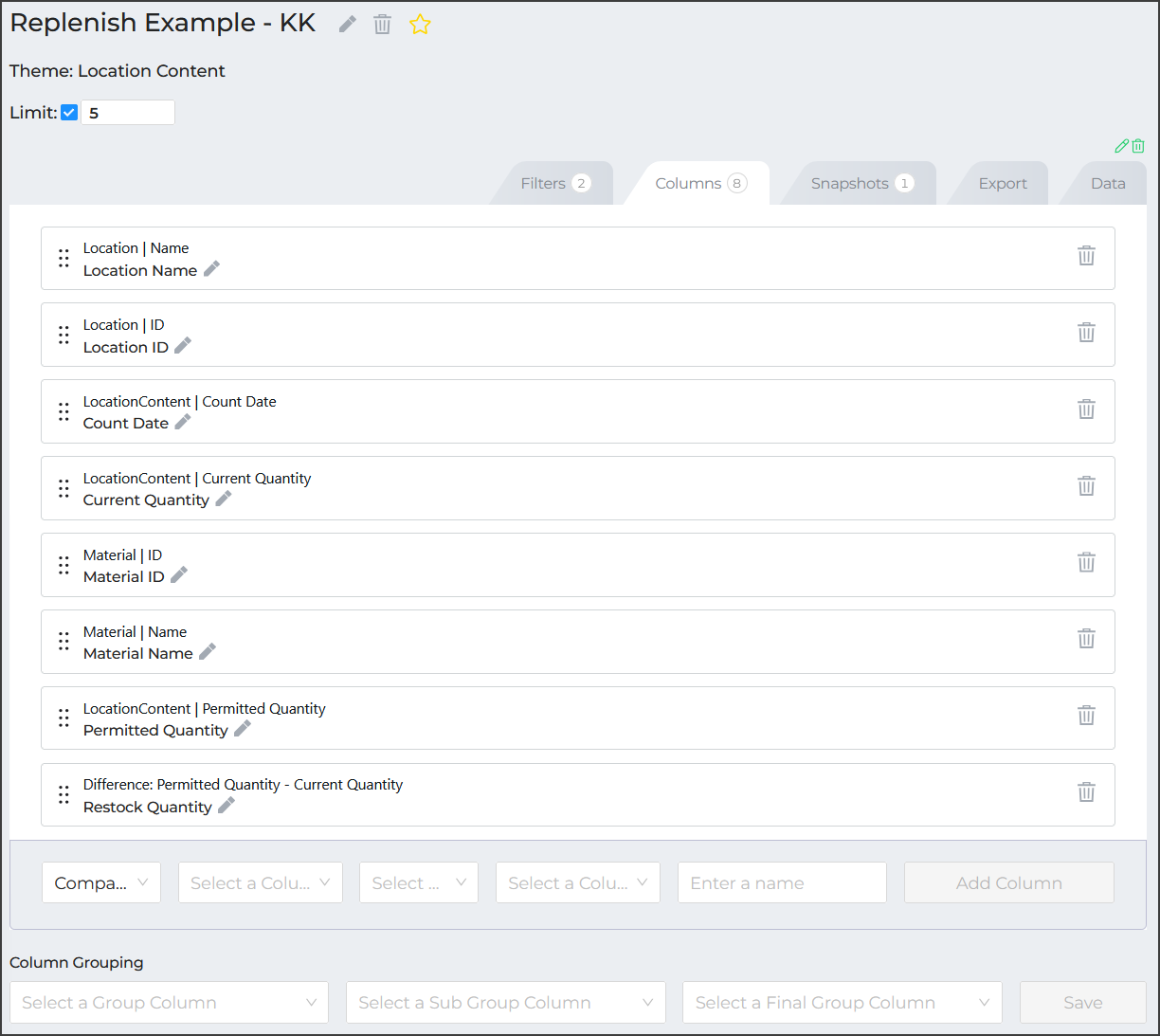

- Navigate to the Reports tab in ItemPath.

- Start a new report using the "LocationContent" theme.

- Add columns to your report. For this example, we will use:

- Location Name

- Count Date

- Current Quantity

- Material ID or Material Name

- Permitted Quantity

- A comparison column set to calculate the difference between Permitted Quantity and Current Quantity.

- Apply filters that match your conditions for replenishment:

- Set "Count Date" to "After Last Week"

- Set "Current Quantity" to "Is Less Than 20."

- To limit the number of replenishment orders generated, we've included a limit value of 5 for the report as a whole.

- Save your report.

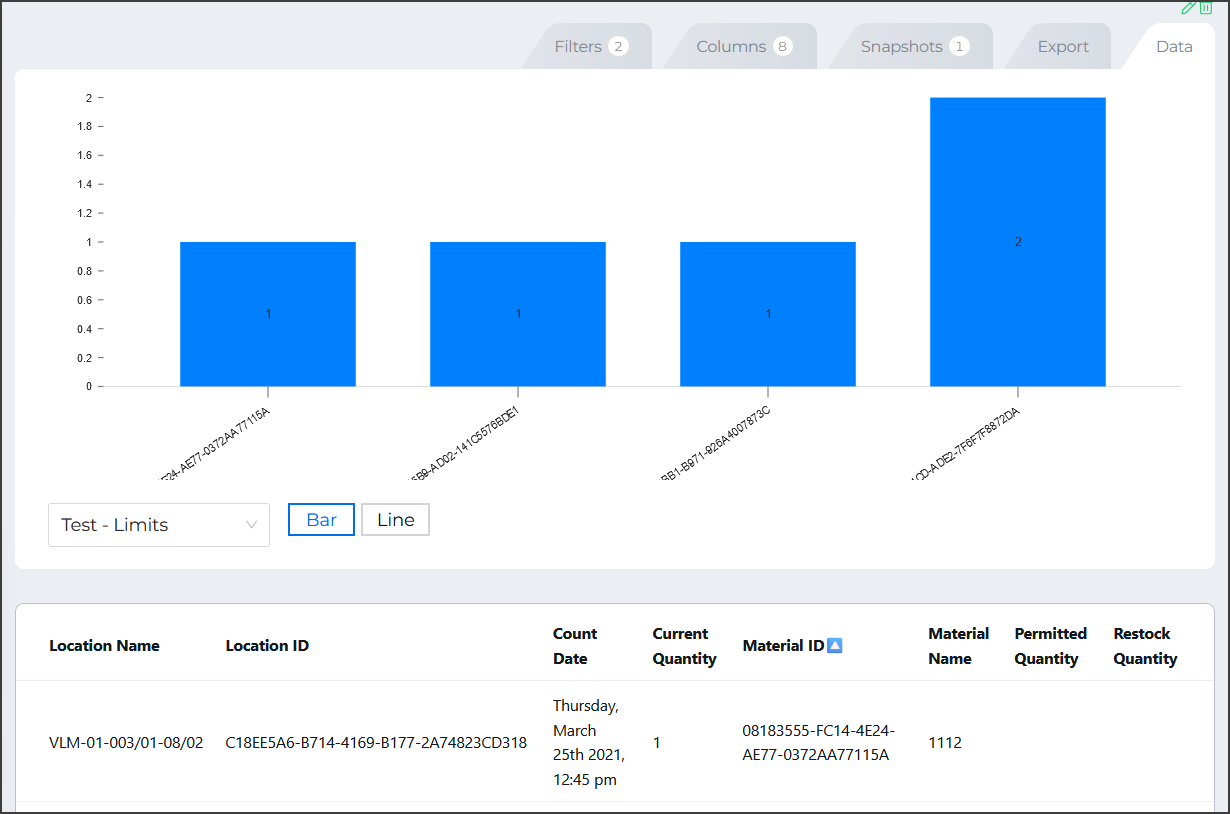

This report will generate a list of 5 inventory items counted in the last week with quantities below 20 units, ensuring replenishment orders are accurate and based on current data (the "Count Date" to "After Last Week"). Adding the difference calculation allows you to specify the quantity to return the location to the maximum permitted quantity.

By carefully planning your scenarios and designing effective reports, you can leverage Order Builder to automate a wide range of warehouse operations and significantly improve overall efficiency. This is includes carefully planning out what data is necessary for the creation of orders, and carefully identifying filters to match your criteria for order creation.